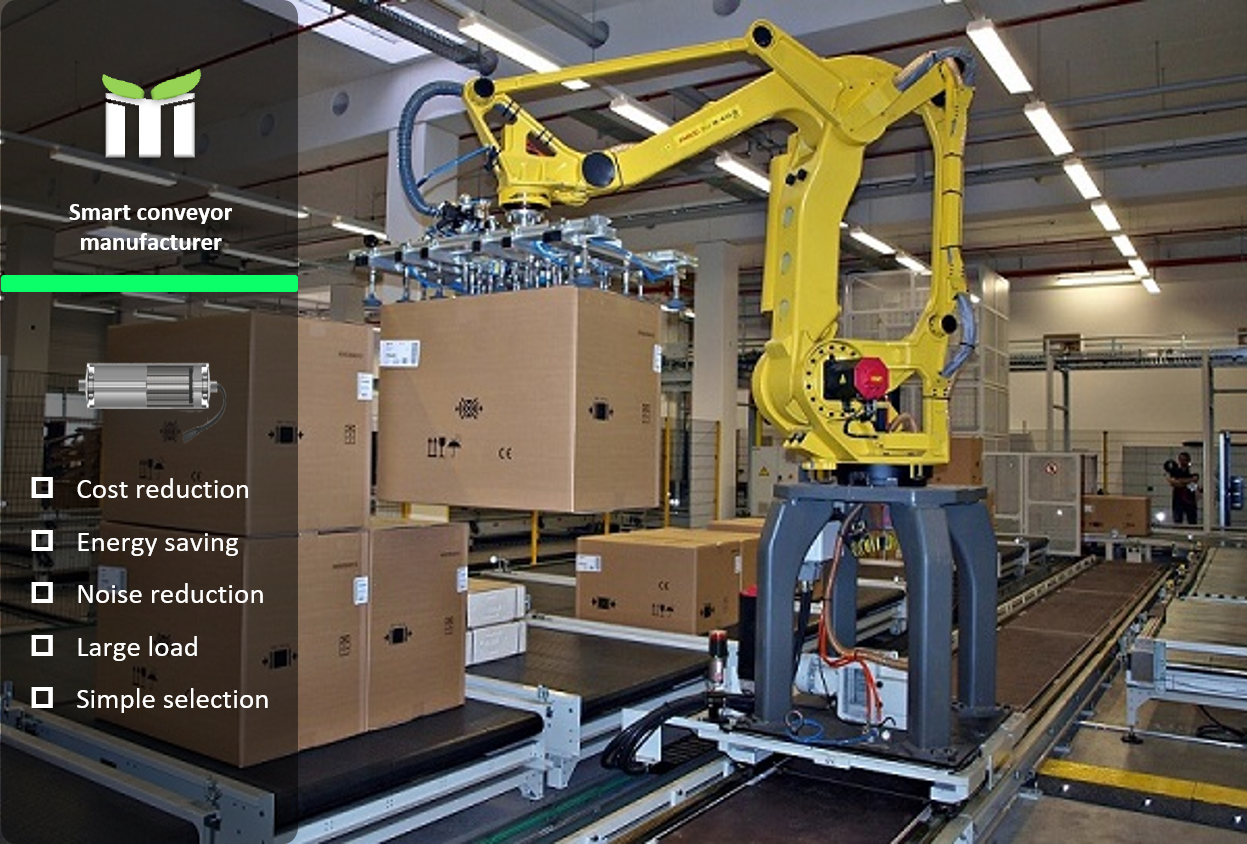

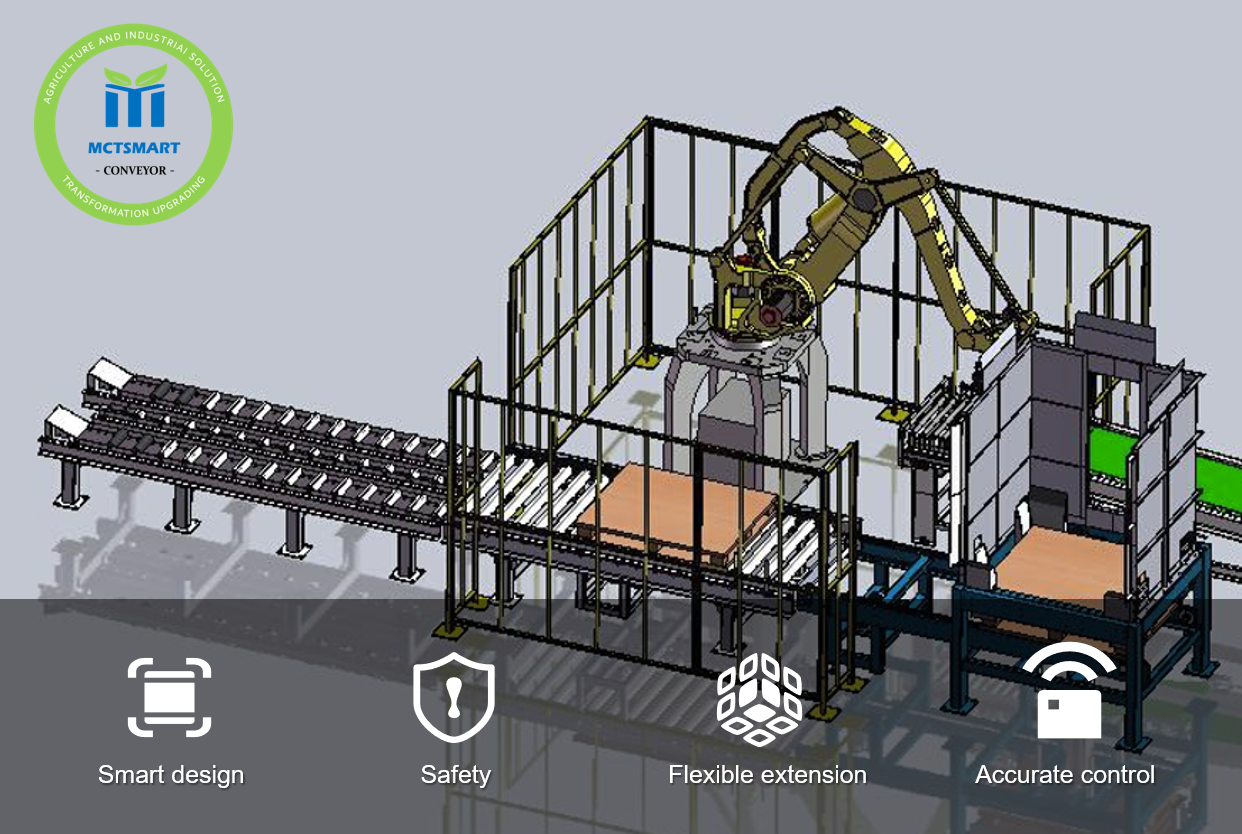

The palletizing system detects the goods by scanning or sensoring, and transfer them by robots. It can be applied for classification, loading, unloading and handling in the production/logistics line.

Palletizing system

▣ High cost-performance: Save at least 50% of the cost.

▣ High intelligence: Help quickly and accurately identify objects such as cartons, sacks, etc., and perform intelligent route planning.

▣ Wide application: It is suitable for goods such as cartons, plastic boxes, bottles, bags, buckets and etc..

☢ Palletizing efficiency: Max.850 pcs/h

☢ Calibration method: Automatic

☢ Protocol: Ethernet

☢ Interface: restful/http/webservice/etc.

☢ Compatible robot: YASKAWA,Kawasaki,ABB,KUKA,etc.

Plan

▣ Research requirements

▣ Design mechanical scheme

▣ Design software scheme

Production

▣ Produce

▣ Internal test

▣ On-site test

Service

✪ One-year maintenance

✪ Technical support

✪ Business consulting

Dezhou Beinuo: palletizing system